News and Project Updates

Tractus-X Comunity Days am 4. und 5. Dezember

SEMICONDUCTOR-X at SEMICON Europa Day 3 & 4

SEMICONDUCTOR-X at SEMICON EuropaDay 2 / 4

From Silos to Ecosystems – fostering collaboration to create value from data

SEMICONDUCTOR-X at SEMICON Europa -Day 1 is in the books

Our SEMICONDUCTOR-X face-to-face meeting

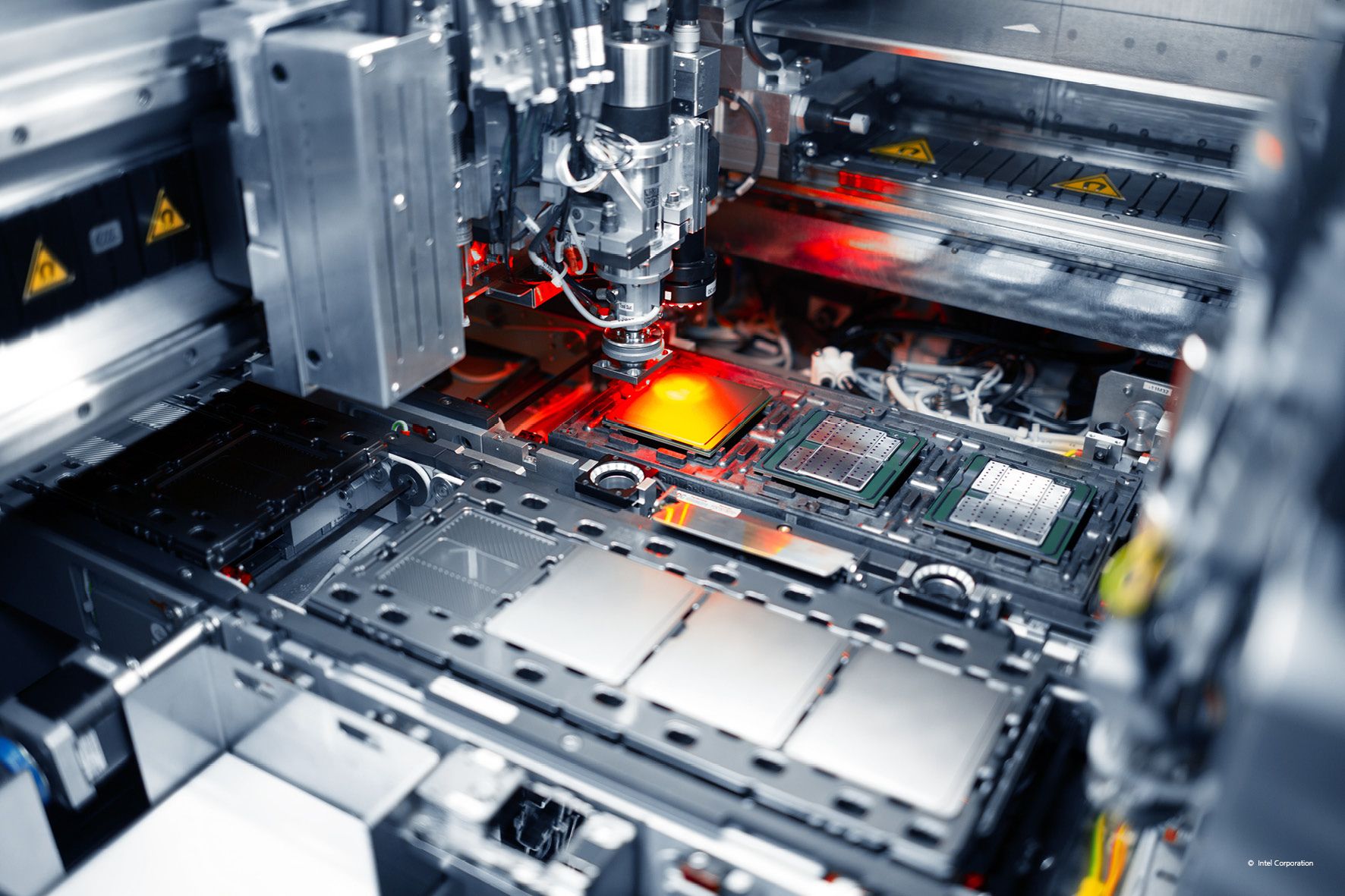

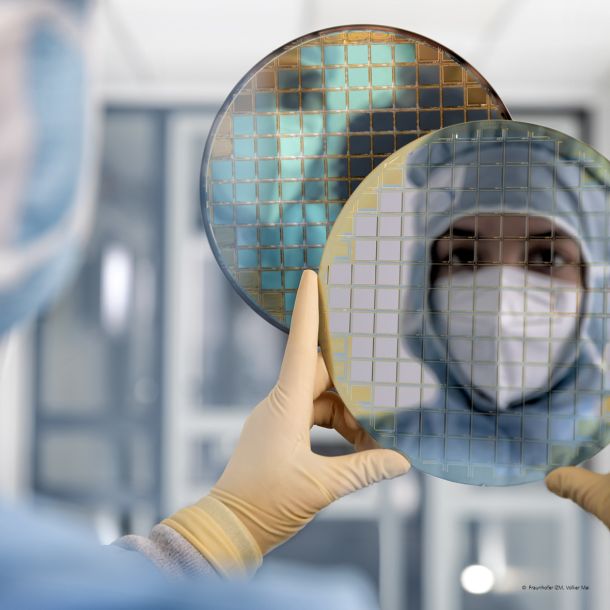

Building Resilience: Digitalizing Europe’s Semiconductor Value Chain

Our project aims to make the European semiconductor industry sustainable and resilient through comprehensive digitalization and the establishment of traceability. Together with our partners, we are developing new data-driven business models and encouraging innovation along the entire value chain. This will entail

Developing digital twins for the semiconductor industry, which digitally model the supply and value chain and enable sovereign and secure data exchange, including their connectivity to other value partners.

Enabling efficient, sustainable and resilient semiconductor operations through industry-wide digitalization and dataspaces for improved value chain traceability.

Enhancing deep digitalization capabilities among value chain partners, especially small and medium businesses (SMBs).

Developing new data-driven business models and encouraging innovation.

Enabling deep interoperability and AI applications by digitalizing every asset and entity in the semiconductor value chain.

Ensuring the availability of semiconductors to key European technologies and industries.

Horizontal. Vertical. Continuous: Industry-specific implementation clusters

Resilient value chains for a heterogeneous integration ecosystem

Building competitive and resilient value chains through the comprehensive heterogeneous integration of partners involved in the packaging technology. The semiconductor industry’s complex inbound supply chain comprises 1000 processing steps and crosses over seventy borders.

Resilient network nodes: digital integration for optimized factory operations

Developing concepts, semantic data models and services for intercompany data exchange in network nodes and the integration of data from and services for factory and supply chain assets in the dataspace.

Sustainability: environmentally optimized processes

Developing the methodology for storing the life cycle assessment data sets in semantic submodels of the digital twin. Optimizations of the digital twin using machine learning and statistical mathematics.

Project Partners

Expert GmbH

(KIWAI Division)

Manufacturing Dresden GmbH

Associated Partners

Solutions & Innovations

Deutschland GmbH

Semiconductor-X is a Manufacturing-X project focused on the semiconductor industry

Semiconductor-X aims to adapt Gaia-X/Catena-X dataspace architecture to the semiconductor industry and to develop advanced digital twins that digitally model critical planning segments of the semiconductor supply and value chain. The project will also integrate established industry standards into this new dataspace architecture.

Interested? Contact us!

Harald Gossner

Intel Deutschland (Project lead)

Tobias Kutzler

Fraunhofer IFF

Digital Logistics Infrastructures and Systems Group Manager

tobias.kutzler(at)iff.fraunhofer.de